History of Welding – From Antiquity to the Present

Introduction

Welding has been one of the key industrial technologies evolving over millennia. From the earliest attempts to join metals in ancient times, through the Industrial Revolution and the invention of electric welding, to modern laser and robotic techniques, the history of welding mirrors the trajectory of technological progress. But did you know that welding and soldering were once considered the same process? Read my article on the history of soldering; don’t its origins seem familiar when you consider the history of welding?

If we define welding as the joining of two metals, then both brazing and soldering fall under this category. So, when does welding truly begin?

My Comment: While at work, I pondered how and when these methods diverged. Historically, soldering and welding shared common roots—ancient artisans used molten metal (often tin or copper) to join components, a process we’d now call soldering. Welding, as we understand it today, began to take shape when people started fusing metals by locally melting and bonding them, rather than merely using additional filler material. In my view, it would be logical and reasonable to consider the strength of the joints. Looking at the development of metal-joining techniques through the lens of joint strength, welding indeed began to play its unique role when it provided connections stronger than those achieved by soldering and brazing. Therefore, a historical turning point could be the invention of electric welding in the 19th century—at that point, welding ceased to be merely a method of joining components and became something that could replace and reinforce structures.

The First Metal Joining Attempts in Antiquity

Humanity began experimenting with melting and joining metals thousands of years ago. In antiquity, thermal processing methods were developed, which laid the foundation for modern metallurgy and welding.

Copper Age (c. 5000-3000 BCE)

- Copper was one of the first metals that humans learned to smelt.

- The oldest evidence of copper smelting was found in Anatolia (Turkey), Egypt, and Mesopotamia.

- Primitive furnaces were used to obtain molten metal, enabling the casting of simple tools and ornaments.

Bronze Age (c. 3300-1200 BCE)

- Discovery that adding tin to copper creates a harder and more durable alloy – bronze.

- Casting techniques were used, pouring molten bronze into molds made of clay or stone.

- The Sumerians, Egyptians, and Chinese mastered the production of bronze weapons and tools.

Iron Age (c. 1200-500 BCE)

- Iron became the dominant metal, though its processing was more challenging due to its high melting point (~1538°C).

- The Hittites developed the technique of hot forging – heating iron to a red-hot state and shaping it with hammers.

- Gradual advancements in sintering iron ore and furnace construction.

Early Metal Joining Techniques (Forge Welding)

- Egyptians and Greeks used heating and hammering techniques to permanently join metals.

- Romans refined forging and riveting techniques, which they used in weapon and tool manufacturing.

19th Century – The Beginnings of Modern Welding

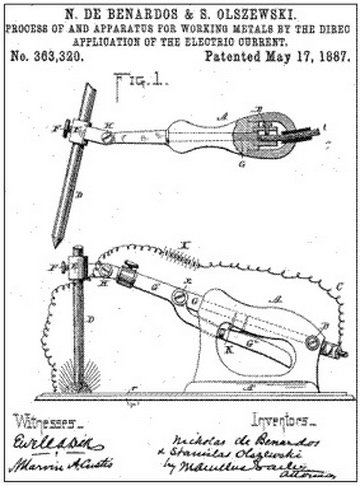

Electric Welding – Benardos and Olszewski (1881-1882)

- Nikolai Benardos and Stanisław Olszewski patented the first arc welding method.

- Their technique involved using a graphite electrode to initiate an electric arc.

- The 1885 patent, named “Elektrogefest,” became the foundation for modern welding.

Fire does not shape metal. The hands that guide it do.

Invention of Coated Electrodes

- Oscar Kjellberg (Sweden, 1907) invented coated electrodes, significantly improving weld quality.

- The coated electrodes created a protective gas, shielding the molten metal from oxidation.

20th Century – Era of Technological Revolutions

Gas Welding (Oxy-Acetylene Welding)

- Edmond Fouché and Charles Picard (France, 1903) invented the oxy-acetylene torch.

- This method was widely used in the automotive and aviation industries (1905-1910).

- World War I (1914-1918) accelerated the large-scale development of gas welding.

Development of MIG/MAG and TIG Welding Methods

- TIG (Tungsten Inert Gas) – 1941, invention of Northrop Aircraft (USA) for the aviation industry.

- MIG/MAG (Metal Inert Gas/Metal Active Gas) – 1948, patented by Airco (USA).

- Plasma Arc Welding (PAW) – 1953, invention of Robert Gage (USA, Union Carbide).

Laser Welding and Automation

- 1960s – General Electric and Bell Labs (USA) experimented with laser beams.

- 1980s – First inverter welding machines (Lincoln Electric, ESAB, Miller Electric).

- 1999 – Automation and robotic welding began (e.g., KUKA, FANUC).

- Laser, hybrid, and ultrasonic welding – development of precise and eco-friendly methods.

- Automation and AI – intelligent welding monitoring systems and industrial robots.

Conclusion

The history of welding shows how humanity has perfected metal joining techniques – from simple forge welding to automated systems controlled by artificial intelligence. Thanks to these innovations, it has become possible to construct modern bridges, ships, airplanes, and space vehicles. The future of welding lies in the continued development of laser technologies, automation, and intelligent control systems.

Did you know that…

Space Fun Fact: Cold Welding in Vacuum!

On Earth, welding requires high temperatures, but in space… all you need is a vacuum! Cold welding is a phenomenon where two perfectly clean pieces of metal can instantly fuse together in space – no heat, no filler, it just happens!

Why? Because in a vacuum, there’s no air to create an oxide layer that would normally keep metals apart. Their atoms “think” they are one single piece and bond without resistance. NASA had to take this into account when designing spacecraft to make sure nothing “sticks” together where it shouldn’t!

This works best with soft metals like aluminum or copper, but don’t bother trying it on Earth – our atmosphere prevents the magic from happening.